The BioFire manufacturing facility is the first of at least four buildings and a parking structure to be built on 60 acres at BioFire’s west campus. The program for the 300,000 sf building consists mainly of clean manufacturing to produce their FilmArray infectious disease diagnostic test kits. The clean space has a large Biochem lab with seven fume hoods used to prepare some of the chemicals required for their diagnostic kit. The building also has approximately 40,000 sf of office area outside the clean manufacturing space and a cafeteria designed to serve 1,400 meals per day. Four truck bays serve a receiving dock and four bays on the opposite end of the building for shipping. Design work began in February 2018. Construction started on the core and shell bid package in August of the same year. Okland Construction reached substantial completion in April of 2020.

The main entrance for the building provides access to the office areas outside the clean space, and one of the cafeteria spaces. Two additional entrances were required through gown-in suites to access the clean manufacturing spaces. Each of the gowning areas has its own industrial laundry facilities. There is a 16-foot wide material handling corridor that runs down the length of the 700-foot long building.

This campus’s design language is taken from BioFire’s headquarters building in Research Park that was completed in 2016. It utilizes insulated concrete tilt-up panels, local Utah sandstone in a 6” x 60” module, and a dramatic 30 foot cantilevered metal panel soffit denoting the main entrance and framing the second-level. The tilt panels were poured with a form liner cast from a hand-carved form created by an artist in France. The main lobby features a sculptural wood stair and a custom-designed lighting feature consisting of 250 individual LED point sources, each individually located in three-dimensions.

The manufacturing floor is covered with approximately five acres of epoxy flooring. Every circuit in the building is on emergency power, backed up by four each two-megawatt emergency generators, two of which are entirely redundant. The generator belly tanks connect to a fueling station with 25,000 gallons that provides fuel for all four generators and fuels BioFire’s fleet vehicles. Solar PV canopies cover 412 parking stalls with a capacity to produce 1.3 megawatts of electricity, roughly enough electricity to power 128 homes.

Viewing Corridor

An architectural catwalk that welcomes viewers into the heart of the building, giving employees and visitors the ability to see each step of the manufacturing process without the need to gown-in.

Freeze Dryer Array

The Freeze Dryer Array room has the capacity to hold over 100 liquid cooled freeze dryers. Power and dedicated chilled water is provided overhead so freeze dryers can be added as production is expanded. Trench drains between back-to-back rows of dryers receive condesate from the array.

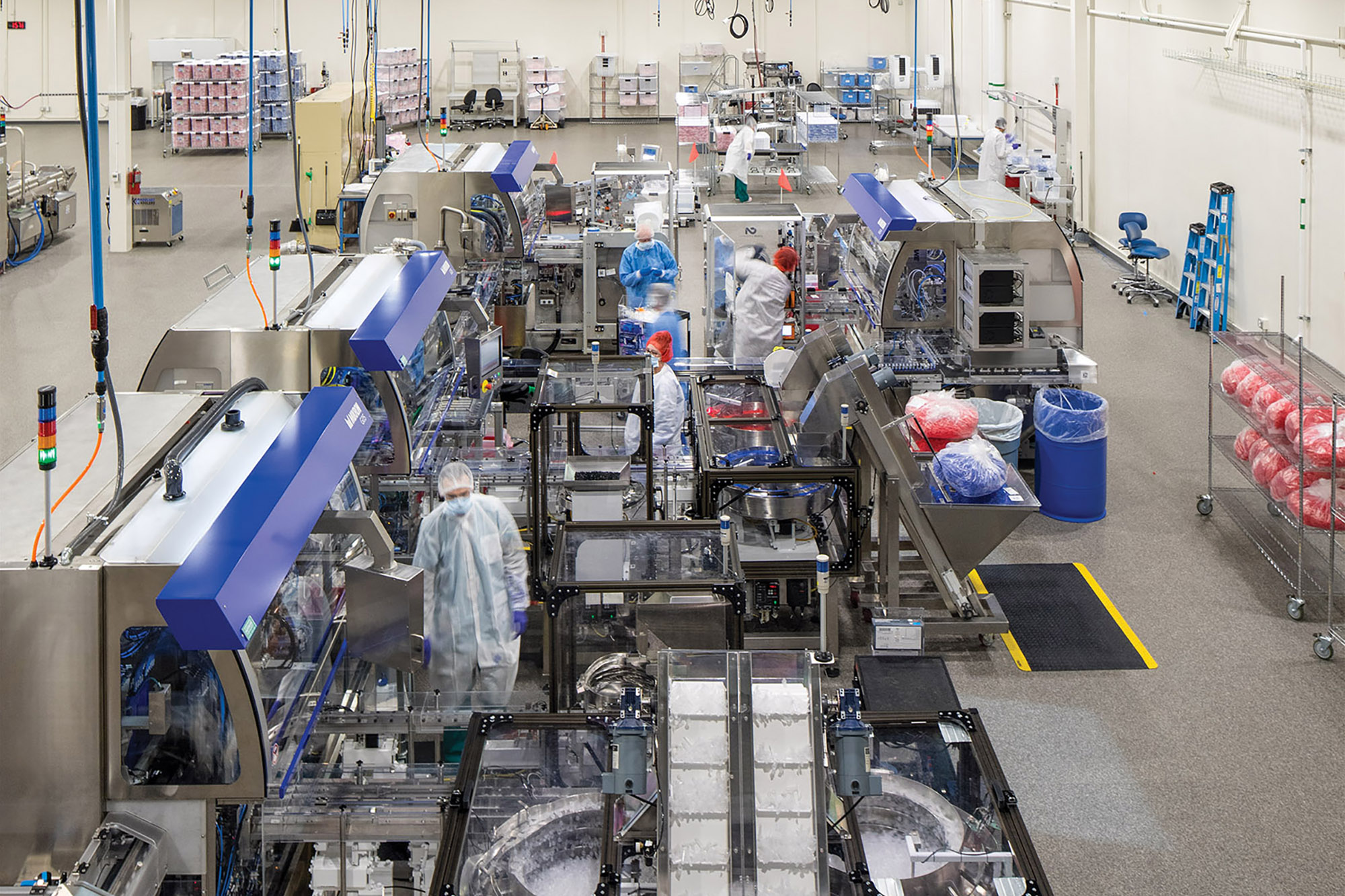

Manual Production Lines in ISO 7 Clean Space

Power, data, and compressed air for each line is provided via ceiling service panels allowing for flexibility and future growth. As production becomes more automated, this space evolves to become a Biochem lab.

Film Array Injection Vial Production

A grid of power and compressed air provided overhead allows for expansion of the semi-automated processes in the manufacturing space. The proprietary aluminum piping system can be hot-tapped at any point without requiring a shut-down.

Packaging

Packaging is the final space in the clean side before product moves in to shipping.

Mechanical Room

There are 13 air handlers and 50 pumps in the 30,000 square foot mechanical room on level two. The mechanical room also houses a large compressor array that provides 120psi air at 900cfm supplying the production line equipment.

Spontaneous Collaboration

Workplace meets hospitality in areas throughout the building where employees are encouraged to collaborate in less formal settings, whether it be in a booth perched over the lobby, or in the cafe looking out towards the Oquirrh Mountains.

An Aperture into the Manufacturing Core

The need to physically separate clean space from the main lobby presented a challenge in communicating the core manufacturing function of the building as part of the lobby experience. By strategically positioning the front desk on axis with the main spine of manufacturing, an “aperture” was integrated into the branding wall to give a peak into the manufacturing function beyond. Adjacent to the front desk, an architectural vitrine is built into the sandstone feature wall, creating a gallery for visitors to see up close the flagship products that the building was designed to produce.

Transparency

True to BioFire’s attitude towards workplace culture, productivity is celebrated and on display. Conference rooms, collaboration hubs, circulation spaces, and manufacturing are visible to the passerby to provide opportunity to spark cross-disciplinary collaboration and innovation.

Nucleus

The first structure for this expansive corporate campus emerged with honesty through a “form follows function” design methodology. Much like the program, negotiating connectivity and separation of neutral and clean spaces, the building carefully expresses harmony in materiality, proportion, and articulation.